Our staff will contact you within 12 hours, You can also contact us through the following ways:

Contact US WhatsApp: +8618766656705

- Email: [email protected]

- Tel: +8618766656705

- Web: https://www.toponechain.com/

1 Shackle performance characteristics

1.1 The shackle body is made of high-quality carbon structure or alloy structure forging and heat treatment, with small size and high strength.

1.2 The shackle test load is 2 times the ultimate working load, and the breaking load is 4 times the ultimate working load.

2 The main purpose and scope of application of shackle

2.1 Shackles can be used for rigging end fittings and are directly connected to the objects to be lifted during hoisting operations.

2.2 Shackles can be used between rigging and end fittings, only for connection.

2.3 When the rigging is used in conjunction with the beam, the shackle can be used to connect the top of the rigging instead of the lifting ring to the lug plate under the beam, which is convenient for installation and disassembly.

2.4 Shackles are the most widely used connection tools in lifting operations, and are mainly used for connection parts that are often installed and disassembled in hoisting.

2.5 D-type shackle is mainly used for single-limb rigging; B-type shackle is mainly used for multi-limb rigging.

2.6 BW, DW type shackles are mainly used in occasions where the rigging will not drive the pin shaft to rotate; BX, DX type shackles are mainly used in occasions where the pin shaft may rotate and occasions for long-term installation.

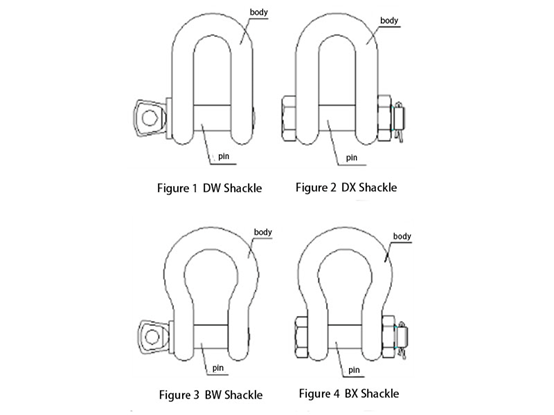

3 Shackle structure diagram

DW, DX and BW, BX type shackle structure diagram shown in Figure 1, Figure 2 and Figure 3, Figure 4.

4 Installation and debugging

4.1 When installing the shackle, hang the shackle directly into the center of the hook, not directly on the hook tip of the hook.

4.2 After the shackle is installed, it should be ensured that the pin shaft can rotate flexibly in the hanging object hole.

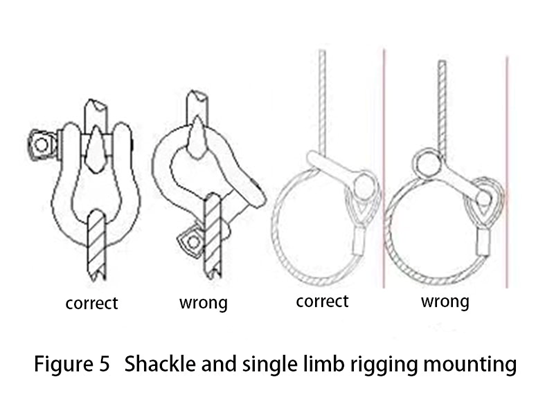

4.3 When installing the shackle and the single-leg rigging, see the figure.

4.4 The thickness of the ear plate of the object to be hung should be moderate. After the shackle is installed, it should be ensured that the buckle body can rotate flexibly, and there is no jamming between the ear plate and the shackle.

5 Use and operation

5.1 The ultimate working load and use range of the shackle are the basis for the test and use of the shackle, and overloading is strictly prohibited.

5.2 During the hoisting process, it is strictly forbidden to collide and impact the hoisted items.

5.3 The lifting process should be as stable as possible, and it is strictly forbidden to stand below or pass on the items.

5.4 Any shackle must be tried to be hoisted before use. The lifting point should be selected to be on the same vertical line as the center of gravity of the lifting weight.

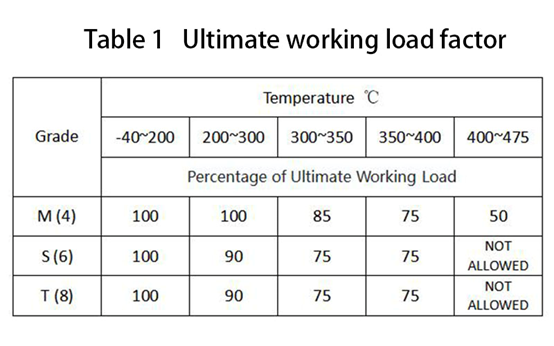

5.5 The ultimate working load factor of shackle in high temperature and low temperature environment, see Table 1.

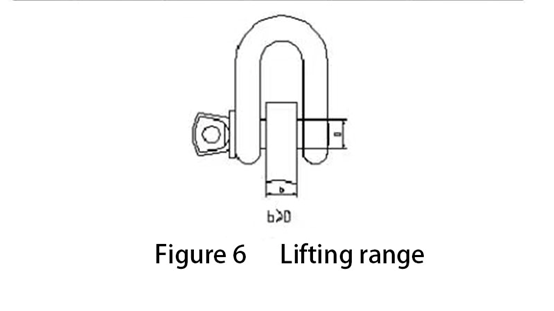

5.6 The thickness of the hanging object lugs and other rigging accessories that are in contact with the shackle pins shall not be less than the diameter of the pins, see figure

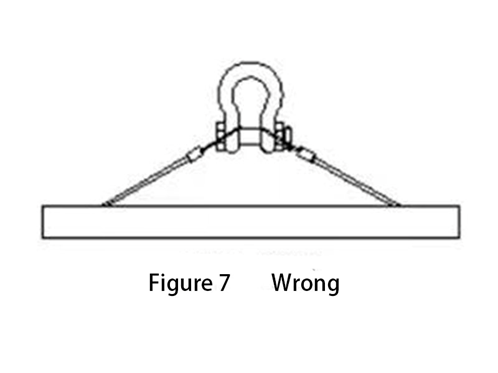

5.7 Shackles are not allowed to be used as shown in Figure 7.

5.8 When the shackle is used, attention must be paid to the direction of the force acting on the shackle structure. If it is not used in accordance with the force requirements, the allowable limit working load of the shackle will be greatly reduced.

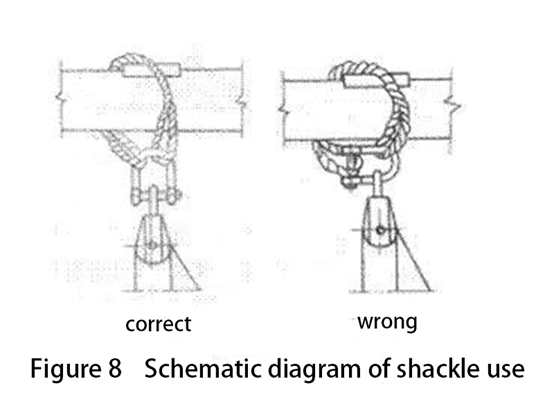

5.9 Schematic diagram of the use method of shackle, see Figure 8.

5.10 After the hoisting operation is completed, the shackle is not allowed to be thrown down from a high altitude, so as to prevent the shackle from being collided and deformed when it falls or internal damage and cracks.

6 Maintenance and Care

6.1 Shackles are not allowed to be stacked, let alone pressure stacking, to prevent the shackles from being deformed.

6.2 When the shackle is cracked and deformed, it is strictly forbidden to repair the shackle by welding and heating and bending.

6.3 The surface of the shackle should be protected against rust, and it is not allowed to store in the environment of acid, alkali, salt, chemical gas, humidity and high temperature.

6.4 Shackles should be kept by special personnel and stored in a ventilated and dry place.

7 Scrap standard

In one of the following situations, the product should be replaced or scrapped.

7.1 When the twist of the shackle body exceeds 10^, the parts should be replaced or scrapped.

7.2 When the corrosion and wear exceed 10% of the nominal size, the parts should be replaced or scrapped.

7.3 If there are cracks on the shackle body and pin shaft after flaw detection, the parts should be replaced or scrapped.

7.4 When the shackle body and pin shaft are obviously deformed, they should be scrapped.

7.5 When cracks and cracks are visible to the naked eye, the parts should be replaced or scrapped.