Our staff will contact you within 12 hours, You can also contact us through the following ways:

Contact US WhatsApp: +8618766656705

- Email: [email protected]

- Tel: +8618766656705

- Web: https://www.toponechain.com/

Shackles are made in a myriad of designs, types sizes, dimensions, and designs With so many choices available, picking the best shackle for your job may be difficult. We've listed some of the basic differences among the most popular kinds of shackles. If you have any concerns you can contact an rigging specialists from our sales team by calling +86 15664466050

Anchor Shackle

Anchor ShackleAnchor shackles and bow shackles are two terms often used interchangeablysince both terms refer to a shackle that has a more of a rounded, larger "O" design.

But it is true that a bow shackle generally features a larger than average space for bows than an anchor. The round design of anchor shackles as well as bow shackles allow them to carry loads from a variety of directions, without generating substantial sideload.

The bigger loop design in an anchor shackle, or bow shackle reduces its overall strength, however it can also take on a strap that is larger.

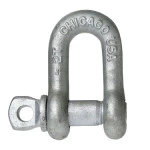

Chain Shackle

Chain ShackleChain shackles can also be referred to as D-shackles. Both are a reference to the "D" shape. A D-shackle is smaller than an anchor or bow shackle and usually is equipped with a threaded pin, and pin close. The shorter loop is intended to take heavy loads mostly in the line.

The racking and side loads can be bent or twisted by a chain or D shackle. These shackles can be found in galvanized and stainless steel. They all are available with different pin choices and pin sizes.

Both galvanized and stainless steel metal provide excellent protection against corrosion and rust, which makes both a worthy option.

In general the galvanized shackles are suitable for industrial use in which moisture isn't an problem. Galvanized steel comes with a fine layer of zinc oxide that helps guard against elements that can cause corrosion and corrosion and. Galvanized steel is also a good choice as it is known to cost less than stainless steel, yet retains the shackle's strength and toughness.

Shackles made of stainless steel are more resistant to corrosion and make them suitable for marine applications. The stainless steel shackles we sell are constructed from stainless steel of type 316 which is known as "marine class."

Type stainless steel marine grade 316 has molybdenum in it, making it invulnerable against ocean mist and spray. This makes it suitable in extreme conditions, humid or high-chloride environment. The shackle made of stainless D Type 316 equipment is perfect for yacht and sailing rigging applications.

Swivel Eye Snap Shackle

Swivel Eye Snap ShackleAn Snap shackle is constructed with a spring-activated mechanism , so it can be operated quickly and easily with just only one hand. These are excellent for jobs where speed is important, or when it needs to be repeatedly connected/disconnected.

They generally have lower limits on working load than similar bolt types or pin-type shackles. Snap Shackles aren't suggested for applications that require a lot of force.

We offer four different types that are all made of Type 316 stainless steel: Swivel Eye, Swivel Jaw, Fixed Snap as well as Rope Snap.

The pin that is used to lock on a shackle may be the deciding factor the best shackle for your task.

Pin styles include pins with loose pins as well as round pins, captive screws, pins along with bolt-type pins.

Shackles with screw pins are well-liked because they have a pin that is simple to connect and disengage.

Captive pin shackles provide an unbreakable pin that can't be taken off out of the back end, which is vital in many marine applications. Captive pins are preferred for marine applications because they're not able to be accidentally dropped into the water.

Bolt-type shackles can be secured using bolt/nut/cotterpin combination and are popular for robust security.

Check out our entire collection on the website