Our staff will contact you within 12 hours, You can also contact us through the following ways:

Contact US WhatsApp: +8618766656705

- Email: [email protected]

- Tel: +8618766656705

- Web: https://www.toponechain.com/

The term alloy sling chain industries refers to manufacturing and application sectors where high-strength alloy steel chains are used for lifting, rigging, and heavy material handling. These industries rely on G80 and G100 alloy steel sling chains for their exceptional tensile strength, durability, and resistance to wear, impact, and extreme working environments.

As a global lifting chain manufacturer, TOPONE CHAIN provides certified alloy sling chain solutions that meet the stringent safety requirements of the world’s most demanding industries.

Alloy sling chains are lifting chains made from quenched and tempered alloy steel, designed specifically for overhead lifting and heavy-duty rigging operations.

They are widely used due to:

High fatigue strength

Excellent impact resistance

Superior working load capacity

Long service life under harsh conditions

Compliance with EN 818-2, ASME B30.9, and ISO standards

TOPONE CHAIN produces alloy sling chains in G80 and G100 grades, suitable for single-leg, double-leg, three-leg, and four-leg chain sling assemblies.

https://www.toponechain.com/grade-43-chain/grade-43-chain-electro-galvanized-finish-half-drum.html

https://www.toponechain.com/grade-43-chain/grade-43-chain-electro-galvanized-finish-half-drum.html

https://www.toponechain.com/grade-100-chain/en818-2-lifting-chain.html

https://www.toponechain.com/grade-100-chain/en818-2-lifting-chain.html

Industry | Main uses |

Construction & Infrastructure | Steel beam lifting, rigging points, structural component handling |

Mining & Quarrying | Heavy machinery lifting, conveyor maintenance, bucket rigging |

Shipbuilding & Offshore | Hull assembly, anchor handling, marine equipment hoisting |

Manufacturing & Engineering | Production line lifting, die handling, machine installation |

Steel Fabrication | Plate lifting, pipe handling, structural component rigging |

Energy & Power Plants | Turbine maintenance, generator lifting |

Transport & Logistics | Cargo loading, container handling |

These sectors form the core of the global alloy sling chain industries, requiring robust and certified chain systems to perform safe and efficient lifting tasks.

Made from premium alloy steel(20Mn2、SCM440、23MnNiMoCr5-4)

G80 & G100 strength grades for high working load limits

Short-link calibrated chain for smooth operation

Precision heat treatment ensuring uniform hardness

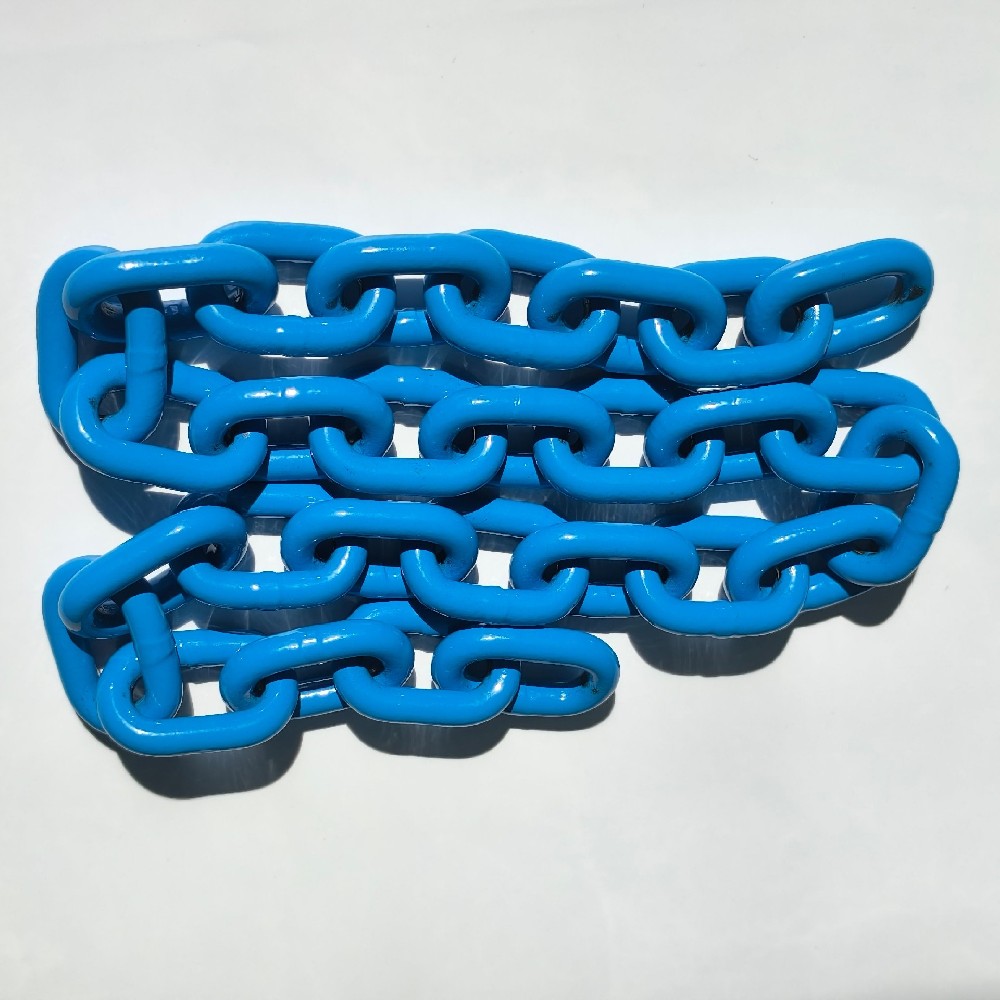

Corrosion-resistant finishes(self-colored / painted / galvanized)

Compatible with all major sling components:hooks、shackles、master links

100% proof-load tested before shipment

Batch traceability ensuring safety and compliance

TOPONE CHAIN supplies complete sling assemblies for all alloy sling chain industries:

Single Leg Chain Sling

2 Leg Chain Sling

3 Leg Chain Sling

4 Leg Chain Sling

Adjustable Chain Sling with Shortening Clutches

Custom Length Slings

Hoist Chain Sets (Manual / Electric)

All slings are assembled with CE / TÜV / GS certified components.

Chain Size (mm) | Grade | WLL (Single Leg) | WLL (4-Leg, 45°) | Proof Load |

6 mm | G80 | 1.12 T | 2.36 T | 2.3× WLL |

8 mm | G80 | 2.0 T | 4.25 T | 2.3× WLL |

10 mm | G100 | 4.0 T | 8.5 T | 2.5× WLL |

13 mm | G100 | 6.8 T | 14.1 T | 2.5× WLL |

Custom | — | Custom | Custom | Custom |

Special materials and coatings available upon request.

All products for alloy sling chain industries meet or exceed:

EN 818-2 / EN 818-4 Lifting Chain Standards

ASME B30.9 Rigging Regulations

ISO 9001:2015 Quality Management

CE / TÜV / GS Certifications

Full load test reports & material certificates

TOPONE CHAIN ensures every chain link is safe, traceable, and reliable.

9 automated production lines

15,000 m² modern factory

OEM/ODM service for global brands

Full product traceability

Competitive factory price

Strong export capability to 80+ countries

We help global alloy sling chain industries operate safer, faster, and more efficiently.

Q1: What makes alloy sling chains different from regular chains?

They use quenched and tempered alloy steel designed specifically for overhead lifting.

Q2: Are alloy sling chains suitable for extreme environments?

Yes — they offer high heat resistance and excellent durability under heavy loads.

Q3: Can I customize chain sling configurations?

TOPONE CHAIN offers custom lengths, components, and sling assemblies for all applications.

Q4: Do you provide certification for each chain sling?

Every chain sling includes a proof load test certificate and batch traceability.

Alloy sling chain industries rely on strong, certified lifting chains to ensure safety and efficiency in heavy operations.

With advanced manufacturing, strict quality control, and global certification, TOPONE CHAIN provides premium G80 and G100 alloy sling chains for all industrial lifting needs.

Request a Quote:

https://www.toponechain.com/contact-us/