Our staff will contact you within 12 hours, You can also contact us through the following ways:

Contact US WhatsApp: +8618766656705

- Email: [email protected]

- Tel: +8618766656705

- Web: https://www.toponechain.com/

Lifting chain slings move every load from precast panels to turbine hubs, yet crews still battle twist, stretch, latch jams, mis-matched grades, surprise rust, hook overloads, and miscalculated angles. This guide tackles each pain point, shows a quick fix, and lists the chain facts behind the solution so you keep cranes rolling and auditors silent.

Sling legs must hang straight, but forklift tines and tangled storage twist links. Twist cuts WLL by up to 20 % and forces hooks open. Lay slings flat, roll each leg until stamps face up, and slide a straightedge to gauge bow. Replace legs twisted more than 60°.

Chain elongation climbs slowly, so crews miss it. Measure five links, compare to original pitch: if stretch > 3 %, break tests show micro-cracks brewing. Mark the sling red and order a new leg.

Chain Ø (mm) | Base Pitch (mm) | Scrap Pitch (+3 %) |

8 | 24 | 24.7 |

10 | 30 | 30.9 |

13 | 39 | 40.2 |

Grit jams spring latches, then hooks eject without warning. Rinse hooks weekly, shoot dry PTFE spray, and cycle the latch ten times. Choose self-locking hooks on G80 or G100 slings so the nose stays shut even if the spring snaps.

Some shops clip new G100 legs onto old G70 chains, thinking “steel is steel.” Inspect every master link stamp: G70, G80, and G100 must never mix in one sling. The sling capacity drops to the lowest grade instantly.

Quick Grade Guide

Stamp | Min. Break vs WLL | Color Band* |

G70 | 2.5 × WLL | Gold |

G80 | 4 × WLL | Black |

G100 | 4 × WLL | Blue |

*Colors vary; always trust the stamp.

Paint flakes and humidity spark red dust overnight. Store slings in vented racks, wipe after rain, and apply light chain oil monthly. For wash-down plants move to 304 or 316 stainless G80 slings; upfront cost climbs but rust removal bills vanish.

Upgraded chains often carry thicker coating and hit the hook saddle. Measure hook opening: it must equal ≥ 4 × chain Ø. If not, swap to a larger clevis or install a connecting link that bridges the gap.

Chain Ø (mm) | Min Hook Throat (mm) |

8 | 32 |

10 | 40 |

13 | 52 |

Leg angle shrinks WLL fast. Use the 60-45-30 rule:

60° between legs → 1 × WLL per leg.

45° → 0.8 × WLL.

30° → 0.5 × WLL.

Print the angle chart, laminate it, and bolt it to the crane cab.

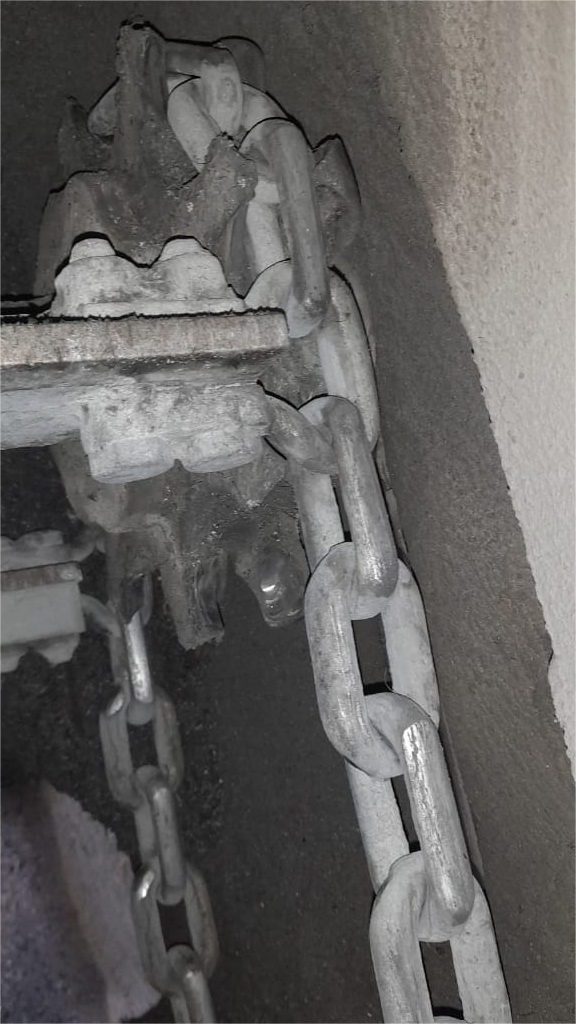

Carousel shows a twisted sling tagged out, an elongation check with a tape, a stuck latch clogged with cement dust, and a worn hook throat measured against a caliper. Train new hires to spot each fault in seconds.

Pain Point | 60-Second Fix | Long-Term Cure |

Twist | Lay flat; untwist | Store on pegboards |

Stretch | Measure pitch | Log data monthly |

Latch jam | Rinse + PTFE | Self-locking hooks |

Mixed grade | Swap low leg | Color-code racks |

Rust | Oil wipe | Stainless upgrade |

Small throat | Add connector | Larger hook spec |

Angle error | Use protractor card | Spreaders or shorter legs |

Solve twist, stretch, latch jams, grade mix-ups, rust, hook mismatch, and angle errors, and your lifting chain slings will stay safe, legal, and profitable—call TOPONE CHAIN today and upgrade your sling room in one order.