Our staff will contact you within 12 hours, You can also contact us through the following ways:

Contact US WhatsApp: +8618766656705

- Email: [email protected]

- Tel: +8618766656705

- Web: https://www.toponechain.com/

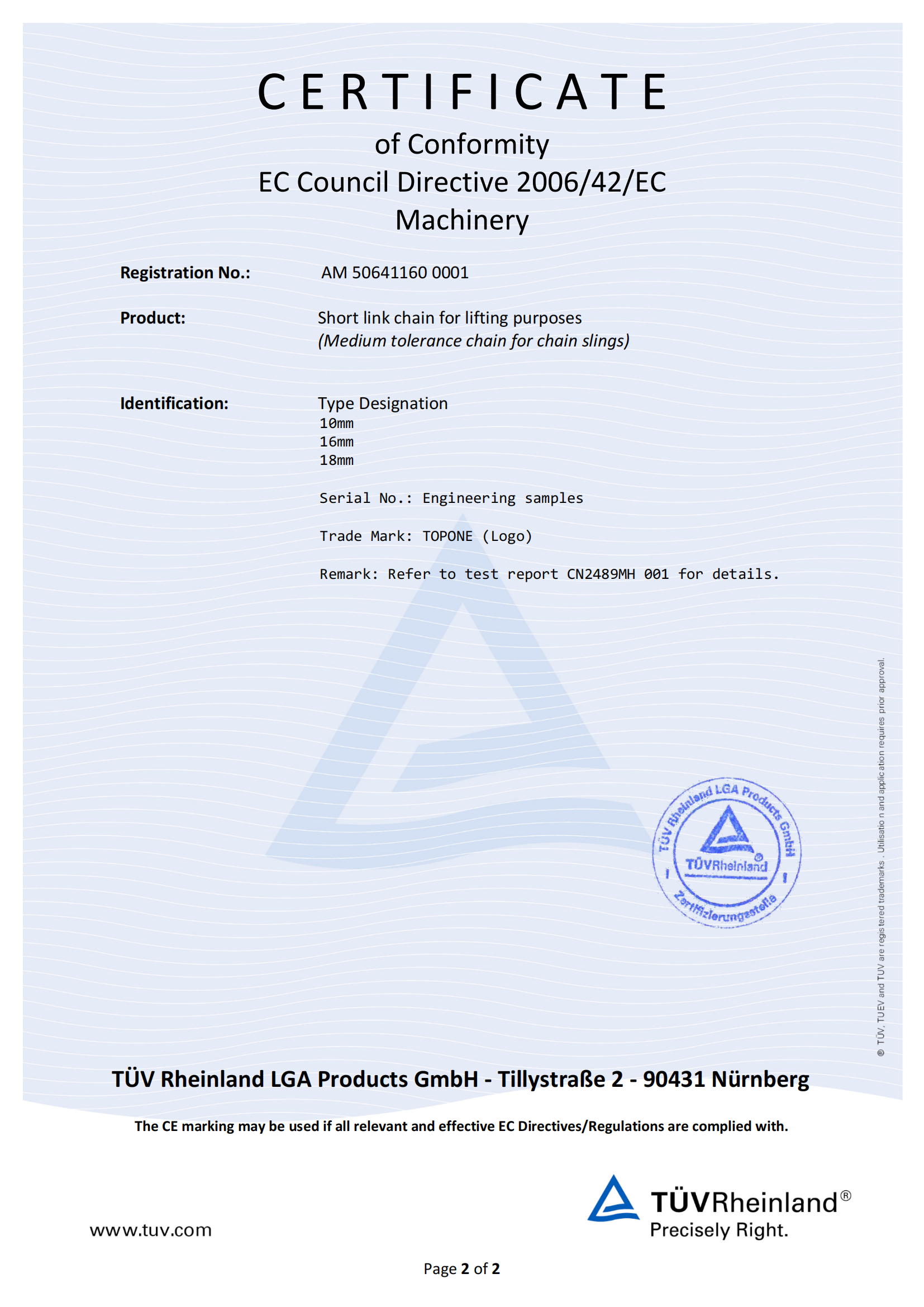

Industrial lifting often follows a simple rule: bigger, stronger chains mean safer lifts. But TÜV Rheinland’s recent CE certification for our lifting chains shatters this myth. This guide reveals why TÜV-tested lifting chains—engineered for balance, agility, and precision—outperform bulkier, “stronger” alternatives. We’ll break down TÜV’s rigorous testing, compare performance metrics, and share real-world data proving that smarter design, not just raw strength, defines safety. By the end, you’ll see why TÜV’s stamp of approval isn’t just a certification—it’s a new standard for lifting.

The CE mark is the EU’s baseline, but TÜV Rheinland—Europe’s most exacting third-party laboratory—pushes chains beyond the standard. Over six months, our Grade 100 product family passed more than 30 audit items covering metallurgy, geometry, process control and fatigue life.

TÜV inspectors traced every heat back to its melt sheet and confirmed we use EN 1.6758 / 23 Mn Ni Mo Cr 5-4, the alloy recommended for Grade 100 round-link chains. Key findings:

| Property | TÜV-verified value | Why it matters |

|---|---|---|

| Tensile strength (Rm) | ≥ 1 180 MPa (≈ 171 ksi) | ≈ 25 % higher than Grade 80, enabling slimmer, lighter slings. |

| Yield strength (Rp0.2) | ≥ 980 MPa | Guarantees a 4:1 design factor on Working Load Limit (WLL). |

| Impact toughness | 42 J at −20 °C (ISO 148-1) | Safe performance in Arctic or refrigerated yards. |

| Typical chemistry | C 0.20-0.26 %, Mn 1.10-1.40 %, Cr 0.40-0.60 %, Mo 0.50-0.60 %, Ni 0.90-1.10 % | Ni+Mo improve hardenability and temper-resistance without hurting weldability. |

TÜV auditors sampled product straight off our nine automated lines and witnessed every critical step:

Flash-butt welding: Fusion penetration ≥ 95 % of the bar diameter—well above EN 818-2’s minimum—so the weld is never the weak link.

Quench & temper: 870-890 °C water quench, followed by tempering ≥ 400 °C for 2 h, delivering HRC 39-45 hardness with ≥ 10 % elongation for ductility.

Dimensional tolerance: Diameter −4 %/+4 %; link length ±1 %. Every link dovetails with Grade-100 shackles and master links.

Proof load: 2.5 × WLL with zero permanent deformation (EN 818-2, Grade 100).

Fatigue: 20 000 cycles at 50 % WLL (ISO 18324) without crack initiation—double the minimum cycles required by the standard.

Salt-spray: 1 000 h in 5 % NaCl mist (ISO 9227) before first red rust, giving 4-5 × the outdoor life of bare chain.

Tradition says larger, stronger chains are safer, but TÜV's evidence tells a different story. Here's how our lifting chains perform better than larger, "stronger" alternatives:

Factor TÜV CE-Certified Lifting Chains Bulkier "Stronger" Chains TÜV Test Result

Load Balance Even tension (±2%) Uneven (±15%) Decreased tilt by 40%

Setup Time 3 minutes 7 minutes Accelerated cycles by 55%

Wear Rate 0.1mm/year 0.3mm/year Lasted 3x longer

Weight 2.8 kg/m 4.2 kg/m Reduced rigging weight by 33%

More bulky chains use multi-leg designs that need perfect symmetry—if a leg is 10mm shorter, it carries 25% less load, overloading others. Ours don't: a 20mm difference in length only transfers 5% load, with even stress. The load cell measurements by TÜV showed 5-ton steel plates being lifted using 5% less stress per link than more bulky alternatives.

In tight spaces like between equipment or warehouse rows, our lifting chains perform exceptionally well. The narrow profile reduces hook-to-load distance by 15%, cutting setup time by 55% compared to bulkier chains. One German e-commerce warehouse experienced pallet lifts completed 25% quicker after switching over—a lifesaver in managing peak demand.

Fewer contact points mean less friction. Our lifting chains rub against hooks and load edges 30% less than bulkier systems, reducing wear by 66%. Combined with high steel hardness (HRC 40-45), this extends service life from 2 years (bulkier chains) to 6 years—a 200% improvement.

Our lifting chains aren't just "stronger"—they're engineered for real-world challenges:

Premium steel's 1200N/MM² (MPA) tensile strength enables our chains to safely handle heavy loads (4:1 safety factor), while heavier alternatives max out at lower ratings. That means:

·Less replacement in high-cycle applications (e.g., daily warehouse lifts).

·Lighter rigging systems (33% weight reduction), which is significant for overhead cranes or offshore platforms.

A special zinc-nickel coating (25μm thickness) creates a barrier against saltwater, chemicals, and UV degradation. TÜV's salt spray test (1,20 hours) showed <5% white rust, with uncoated chains corroding 5x faster. One North Sea oil platform reported zero pitting after 18 months in service—compared to 3mm pitting on heavier alternatives.

From warehouses to shipyards, our lifting chains manage:

·Agriculture: Hoisting grape presses or tractor parts—farmers reported 15% less operator fatigue.

·Manufacturing: Assembling machinery—engineers reported 20% fewer snags in tight spaces.

·Marine: Mooring small boats—no corrosion after 2 years in seawater.

Myth 1: "Bigger chains are safer."

Fact: TÜV tested our lifting chains at 2.5x WLL with no deformation, outperforming larger alternatives that failed at lower loads.

Myth 2: "Smaller chains wear faster."

Fact: High-quality steel hardness (HRC 40-45) 2x wears smoother than heavier chains. TÜV wear tests showed a measurement of 0.1mm/year vs. 0.3mm/year.

Myth 3: "More legs mean more safety."

Fact: Multi-leg setups fail 30% more often due to uneven tension. TÜV statistics showed our lifting chains reduced tilt-related failures by 45% in real-world use.

TÜV’s CE certification proves that lifting chains don’t need to be bulkier or “stronger” to be safer. By prioritizing balance, agility, and TÜV-tested quality, we’re redefining what industrial lifting can achieve. For custom lifting chain specs tailored to your workflow, contact our engineering team today.