Our staff will contact you within 12 hours, You can also contact us through the following ways:

Contact US WhatsApp: +8618766656705

- Email: [email protected]

- Tel: +8618766656705

- Web: https://www.toponechain.com/

Check for the bold "G80" stamp on the link or tag, then look for the TAU-issued CE mark and the standard code—NACM96, NACM84/90 or ASTM 80. When all three appear together you get world and U.S. compliance and lock out counterfeits before they ever reach your hook.

Read the engraved Working Load Limit (WLL) and compare it with your heaviest lift. A true G80 alloy chain—made from 20Mn2 steel—must withstand at least 4 × WLL as proof load and 8 × WLL as minimum break load. Matching the rating to the task stops guesswork and keeps people safe.

Quick Capacity Guide for G80 (20 Mn 2) | 8 mm | 10 mm | 13 mm | 16 mm |

Typical WLL (t) | 2.0 | 3.2 | 5.3 | 8.0 |

Proof Load ≈ 4× WLL (kN) | 78 | 126 | 206 | 314 |

Break Load ≈ 8× WLL (kN) | 156 | 252 | 412 | 628 |

Values based on EN 818-2 formulas; always confirm with your supplier's test sheet.

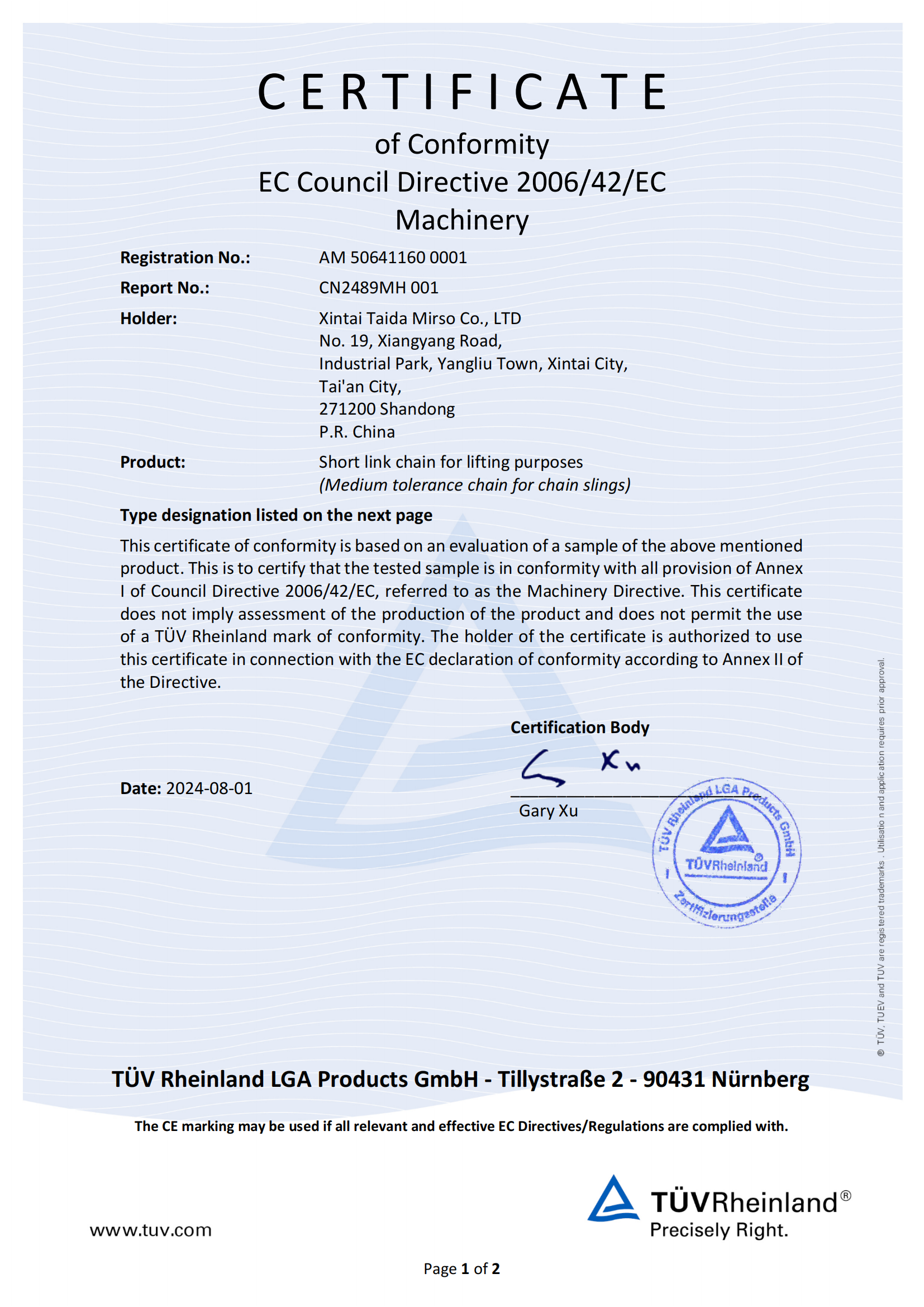

Flip over the tag and look for the CE mark alongside a standalone TÜV badge. Together they confirm the chain met EU safety directives and passed mechanical testing by a third party. If either logo is absent, shop elsewhere—downtime and injury cost far more than a certified chain.

Trace the links with your finger: the even, smooth finish indicates the manufacturer forged 20Mn2 alloy steel, quenched and tempered it for high tensile strength and extended fatigue life. Plain carbon steel rusts, chips and stretches; 20Mn2 maintains its integrity under shock load after shock load.

Ask for batch-specific PDFs: tension curves, break-force graphs and elongation figures. Reputable manufacturers email them within minutes, and the numbers equal EN 818-2 formulas. No report? No order.

Safety doesn't end at delivery. Document visual inspections every shift, dimensional inspections every quarter and destructive tests whenever your local standard requires. Steel fatigue doesn't take a shortcut; routine re-tests optimize service life and prevent unpleasant surprises.

If your G80 lifting chain passes all six gates—clear marking, auditable certification, 20 Mn 2 alloy verification, actual test records, and recurrent re-inspection—you lift with total confidence, protect every crew member and keep downtime at zero. Fail just one step and you jeopardize safety; pass them all and you maximize productivity, project after project.

For more information please contact us→