Our staff will contact you within 12 hours, You can also contact us through the following ways:

Contact US WhatsApp: +8618766656705

- Email: [email protected]

- Tel: +8618766656705

- Web: https://www.toponechain.com/

When working with overhead cranes, the choice of crane chains and their accessories determines the safety and efficiency of every lift. From a simple crane chain hook to complete crane lifting chains, these components form the backbone of industrial rigging. With the rise of specialized projects, custom chain slings have also become popular, offering tailored solutions to unique lifting challenges. This guide explains how to select, use, and maintain crane chain sling systems for heavy-duty applications.

Crane chains are manufactured from quenched and tempered alloy steel, designed to handle dynamic and static loads in demanding environments. Unlike wire ropes or synthetic slings, chains offer superior durability and resistance to abrasion, heat, and impact.

Key features include:

High Strength: Ideal for repetitive lifting in construction, steel plants, and shipyards.

Flexibility: Links adjust easily to different load shapes.

Durability: With proper care, crane chains can outlast other lifting options.

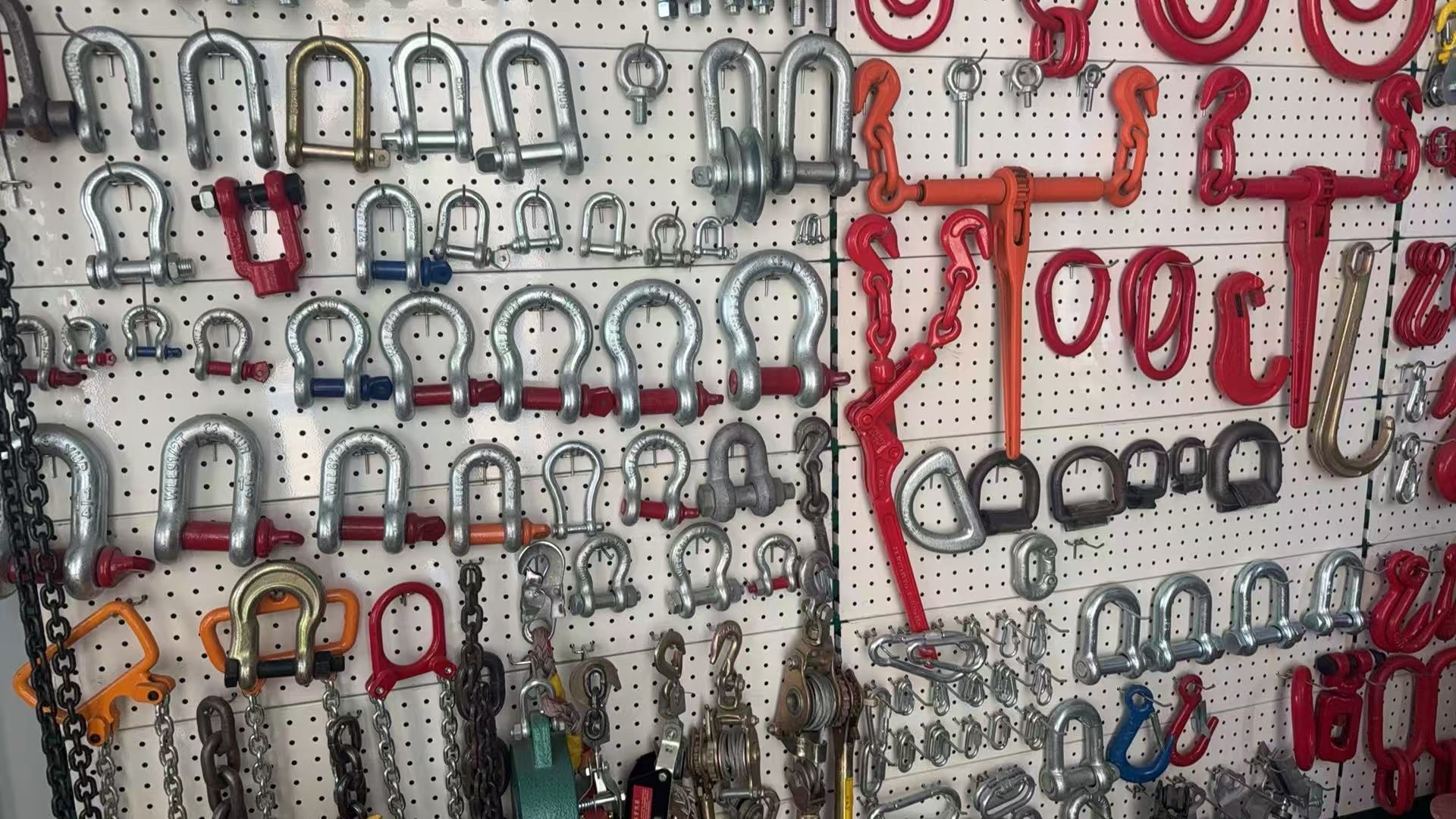

A crane chain hook is more than just a connector; it is a critical component that secures the load. Depending on the application, hooks can be:

Sling hooks with safety latches for general lifting.

Self-locking hooks that automatically close under load for maximum safety.

Foundry hooks designed for extreme heat and molten metal handling.

Choosing the right hook ensures both efficiency and compliance with international standards such as ASME B30.10 and EN 1677.

A crane chain sling combines chains, hooks, and master links into a complete lifting assembly. Common configurations include:

Single-leg slings for vertical lifting.

Double-leg slings for balanced loads.

Three-leg and four-leg slings for complex lifting operations.

Each crane chain sling must have a clear Working Load Limit (WLL) tag, indicating its safe lifting capacity at different angles.

While wire ropes and web slings are widely used, crane lifting chains provide unique advantages:

Feature | Crane Lifting Chains | Wire Rope Slings | Web Slings |

Durability | Extremely high | Medium | Low |

Heat Resistance | Up to 400°C (depending on grade) | Moderate | Poor |

Flexibility | High, adapts to load | Good | High |

Service Life | Long | Medium | Short |

Inspection | Easy to detect wear | Requires detailed checks | Can hide internal damage |

This comparison shows why heavy industries often prefer chains for crane lifting operations.

Not every lifting scenario can be solved with standard equipment. Custom chain slings are designed to meet specific operational requirements, such as:

Unique leg lengths for irregularly shaped loads.

Specialized hooks for unusual attachment points.

Upgraded chain grades (e.g., G100 or G120) for higher WLL.

Coated or stainless steel chains for corrosive environments.

A professional manufacturer can provide engineering support, load charts, and certifications to ensure each custom chain sling meets strict safety standards.

Whether using a crane chain hook or complete crane lifting chains, safety must come first. Essential practices include:

Inspection: Look for wear, elongation, or cracks before every lift.

Load Control: Never exceed the WLL indicated on the tag.

Angle Awareness: Keep sling angles within recommended limits to avoid overload.

Temperature Limits: Do not use chains beyond their certified heat resistance.

Storage: Store in a dry place, protected from chemicals and moisture.

From the smallest crane chain hook to fully engineered custom chain slings, crane chains remain essential for safe and efficient lifting. By selecting the right crane chain sling and maintaining strict safety practices, industries can reduce risks, improve efficiency, and extend the service life of their equipment.