Our staff will contact you within 12 hours, You can also contact us through the following ways:

Contact US WhatsApp: +8618766656705

- Email: [email protected]

- Tel: +8618766656705

- Web: https://www.toponechain.com/

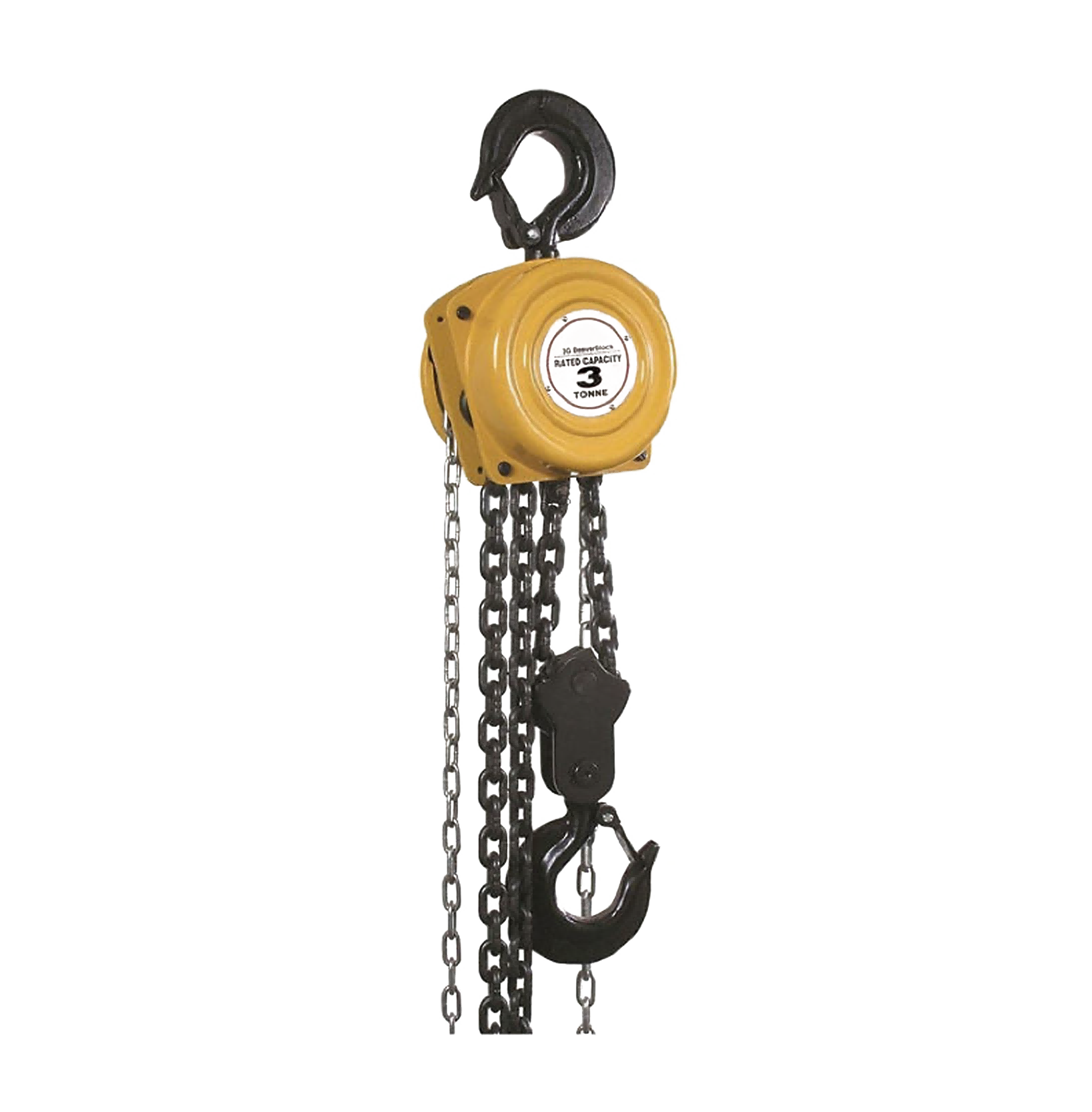

Chain blocks are essential for lifting heavy loads in workshops, construction sites, and industrial facilities. Among the most common models, 2 ton and 3 ton chain blocks are favored for their balance of power and versatility. This guide compares their load limits, technical specs, safety features, and real-world applications to help you choose the right tool for your tasks.

The working load limit (WLL) defines the maximum weight a chain block can safely lift under normal conditions. A 2 ton chain block handles 2,000 kg, while a 3 ton model manages 3,000 kg. Both follow a strict 4:1 safety factor, meaning their minimum break strength (the force needed to snap the chain) is 8,000 kg (2 ton) and 12,000 kg (3 ton).

For light tasks—like lifting engines in auto repair shops or repositioning farm tools—the 2 ton block is sufficient. However, heavy-duty jobs, such as moving steel beams on construction sites or securing cargo in ports, demand the 3 ton block to avoid overloading and ensure safety.

The 2 ton and 3 ton chain blocks differ in physical dimensions, weight, and materials to accommodate their load capacities.

Specification | 2 Ton Chain Block | 3 Ton Chain Block |

Dimensions (L×W×H) | 12×8×6 inches | 14×10×7 inches |

Weight | 15 kg | 22 kg |

Material | Grade 70 Alloy Steel | Grade 80 Alloy Steel |

Chain Diameter | 8mm | 10mm |

The 2 ton block’s compact size (12×8×6 inches) and lightweight design (15 kg) make it easy to maneuver in tight spaces like small workshops. Its Grade 70 alloy steel chain balances strength and flexibility, ideal for occasional use. In contrast, the 3 ton block uses thicker Grade 80 steel (10mm chain diameter) and a bulkier frame (14×10×7 inches, 22 kg) to handle heavier loads without stretching, making it a workhorse for daily industrial tasks.

Choosing between a 2 ton and 3 ton chain block depends on your industry and task.

Industry | 2 Ton Chain Block | 3 Ton Chain Block |

Workshops | Lifting engines, tools | Rarely needed |

Construction | Light materials (wood, small beams) | Steel beams, generators |

Agriculture | Tractors, farm equipment | Heavy machinery (combines) |

Ports | Not recommended | Shipping containers, cargo |

In auto repair shops, the 2 ton block excels at lifting engines or adjusting machinery—its compact size lets technicians work in confined spaces. For construction sites, the 3 ton block is irreplaceable: it safely lifts steel beams and generators, which often exceed 2.5 tons. Similarly, in agriculture, the 2 ton block handles tractors and tools, while the 3 ton block manages heavy machinery like combines or irrigation systems.

Both models prioritize safety, but the 3 ton block adds extra safeguards for high-stress environments.

The 2 ton block includes a dual-pawl braking system to prevent accidental drops, complying with ASME B30.26 standards for general use. The 3 ton block, however, features a dual-pawl system plus a spring-loaded safety catch to secure loads during prolonged lifts. This design meets OSHA 1910.184, a stricter standard for construction and industrial sites, ensuring compliance in high-risk settings.

Regular maintenance ensures both blocks perform reliably. The 2 ton block requires monthly lubrication with light grease to prevent rust and jams. For the 3 ton block, bi-weekly oiling is necessary due to its heavier use and thicker chain. Inspect both for chain wear: replace 2 ton chains when they stretch by 10%, and 3 ton chains at 8% elongation to avoid failure.

While the 2 ton block is cheaper upfront ($150–$200), the 3 ton block ($250–$350) offers better long-term value. In heavy use, the 2 ton block lasts 5–7 years, while the 3 ton block endures 8–10 years. For occasional tasks, the 2 ton block saves money; for daily industrial use, the 3 ton block’s durability reduces replacement costs.

The 2 ton chain block is ideal for light, versatile tasks in workshops or small farms, thanks to its compact size and affordability. The 3 ton block, with its higher load capacity and robust design, is built for heavy-duty industrial applications like construction and port operations.

When choosing, consider your load size, environment, and usage frequency. Always opt for certified models (ASME/OSHA) and follow maintenance guidelines to ensure safety and longevity.