Our staff will contact you within 12 hours, You can also contact us through the following ways:

Contact US WhatsApp: +8618766656705

- Email: [email protected]

- Tel: +8618766656705

- Web: https://www.toponechain.com/

There are several benefits to using DIN 22252 chain in industrial applications. Here are some of the key advantages:

Strength and durability: DIN 22252 chain is made of high-quality alloy steel, which provides excellent tensile strength and corrosion resistance. This makes it ideal for use in heavy-duty applications that require a strong and durable chain.

Resistance to wear and tear: The DIN 22252 chain is designed to resist wear and tear, even under heavy use. This helps to extend the lifespan of the chain, reducing maintenance and replacement costs.

Versatility: DIN 22252 chain is available in a variety of sizes and configurations, making it suitable for use in a wide range of industrial applications. It can be used for conveying heavy loads, lifting and hoisting equipment, and more.

Precision engineering: DIN 22252 chain is manufactured to strict specifications, ensuring precise dimensions and consistent quality. This helps to ensure reliable performance and reduces the risk of chain failure.

Compatibility with other components: The DIN 22252 chain is designed to work seamlessly with other components, such as sprockets and attachments, to form a complete chain drive system. This makes it easy to integrate into existing machinery and equipment.

DIN 22252 Round Link Chain is used for Armored Face Conveyors (AFC), Beam Stage Loaders (BSL), road header machines, coal plows and other equipment that requires this type of chain.

acc to DIN 22252 or PN-G-46701 or GB/T-12718 or GOST 25996 standard

DIN 22252 mining chain

Round link chain, round steel link chain, round link mining chain, DIN 22252 mining chain, mining conveyor chain, flight bar chain system

DIN 22252 chain is a type of chain commonly used in industrial applications. It is designed and manufactured in accordance with the German standard DIN 22252, which specifies the dimensions, materials, and other characteristics of the chain.

The DIN 22252 chain is known for its strength, durability, and resistance to wear and tear. It is typically made of high-quality alloy steel, which provides excellent tensile strength and corrosion resistance.

This type of chain is used in a wide range of applications, including mining, construction, and heavy machinery. It is often used for conveying heavy loads, such as in conveyor systems, or for lifting and hoisting equipment.

The DIN 22252 chain is available in a variety of sizes and configurations to meet different application requirements. It is typically assembled with other components, such as sprockets and attachments, to form a complete chain drive system.

Production according to DIN 22252 or PN-G-46701 or GB/T-12718 or GOST 25996 standard

Application:

Armoured Face Conveyors, roadheader machines, coal plows, Beam Stage Loaders, other equipment that requires this type of chain.

Dimension | |||||

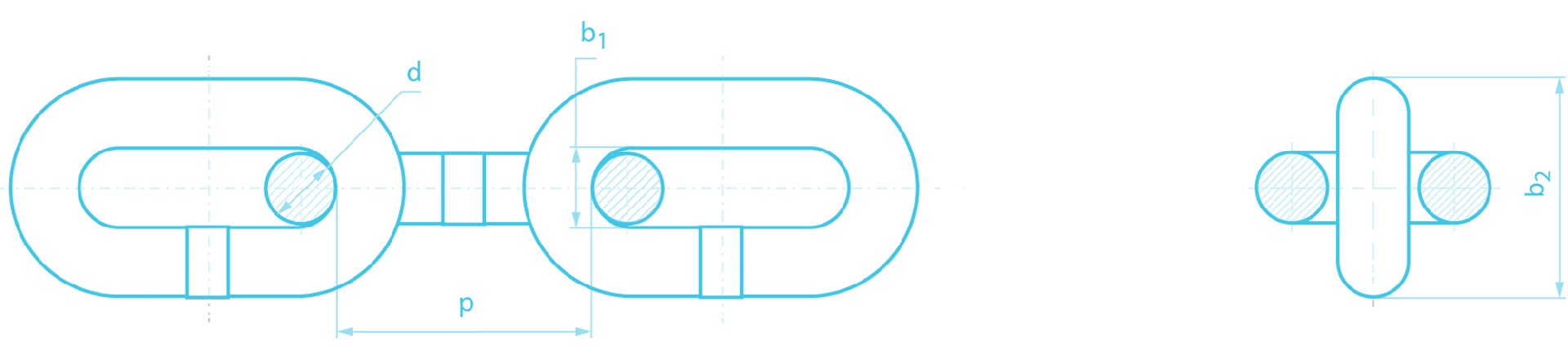

Chain Size d x p | Diameter d | Pitch P | b1min. | b2 max. | Weight |

(mm) | (mm) | (mm) | (mm) | (mm) | (kg/m) |

14 x 50 | 14 ±0.4 | 50 ±0.5 | 17 | 48 | 4.0 |

18 x 64 | 18 ±0.5 | 64 ±0.5 | 21 | 60 | 6.6 |

19 x 64.5 | 19 ±0.6 | 64.5 ±0.6 | 22 | 63 | 7.4 |

22 x 86 | 22 ±0.7 | 86 ±0.9 | 26 | 73 | 9.5 |

24 x 86 | 24 ±0.7 | 86 ±0.9 | 28 | 79 | 11.6 |

24 x 87.5 | 24 ±0.7 | 87.5 ±0.9 | 28 | 79 | 11.5 |

26 x 92 | 26 ±0.8 | 92 ±0.9 | 30 | 85 | 13.7 |

30 x 108 | 30 ±0.9 | 108 ±1.1 | 34 | 97 | 18.0 |

34 x 126 | 34 ±1.0 | 126 ±1.3 | 38 | 110 | 22.7 |

38 x 126 | 38 ±1.1 | 126 ±1.4 | 42 | 121 | 30.1 |

38 x 137 | 38 ±1.1 | 137 ±1.4 | 42 | 121 | 29.0 |

42 x 137 | 42 ±1.1 | 137 ±1.4 | 48 | 137 | 36.9 |

42 x 146 | 42 ±1.1 | 146 ±1.5 | 48 | 137 | 36 |

Notice: l All anti-corrosive coatings decrease the chain mechanical properties l Other sizes can be customized according to customer requirements | |||||

Mechanical Properties | |||||||

ChainSize d x p | Chain Grade | Test Force | Breaking Force min. | Unit Elongation at test force max. | Unit Elongation at breaking force min. | Deflection f min. | Fatigue Resistance min. |

(mm) | (KN) | (KN) | (%) | (%) | (mm) | (cycles) | |

14x50 | B | 150 | 190 | 1.4 | 14 | 14 | 50.000 |

C | 200 | 250 | 1.6 | 14 | 14 | 70.000 | |

C++ | 200 | 280 | 1.6 | 18 | 14 | 90.000 | |

D | 250 | 310 | 1.9 | 16 | 14 | 90.000 | |

18x64 | B | 260 | 320 | 1.4 | 14 | 18 | 50.000 |

C | 330 | 410 | 1.6 | 14 | 18 | 70.000 | |

C++ | 330 | 460 | 1.6 | 18 | 18 | 90.000 | |

D | 410 | 510 | 1.9 | 16 | 18 | 90.000 | |

19x64 19x64.5 | B | 290 | 360 | 1.4 | 14 | 19 | 50.000 |

C | 360 | 450 | 1.6 | 14 | 19 | 70.000 | |

C++ | 360 | 510 | 1.6 | 18 | 19 | 90.000 | |

D | 450 | 565 | 1.9 | 16 | 19 | 90.000 | |

22x86 | B | 380 | 490 | 1.4 | 14 | 22 | 50.000 |

C | 490 | 610 | 1.6 | 14 | 22 | 70.000 | |

C++ | 490 | 680 | 1.6 | 18 | 22 | 90.000 | |

D | 610 | 760 | 1.9 | 16 | 22 | 90.000 | |

24x86 24x87.5 | B | 460 | 570 | 1.4 | 14 | 24 | 50.000 |

C | 580 | 720 | 1.6 | 14 | 24 | 70.000 | |

C++ | 580 | 815 | 1.6 | 18 | 24 | 90.000 | |

D | 720 | 900 | 1.9 | 16 | 24 | 90.000 | |

26x92 | B | 540 | 670 | 1.4 | 14 | 26 | 50.000 |

C | 640 | 850 | 1.6 | 14 | 26 | 70.000 | |

C++ | 700 | 960 | 1.6 | 18 | 26 | 90.000 | |

D | 790 | 1060 | 1.9 | 16 | 26 | 90.000 | |

30x108 | C | 850 | 1130 | 1.6 | 14 | 30 | 70.000 |

C++ | 950 | 1280 | 1.6 | 18 | 30 | 90.000 | |

D | 1050 | 1400 | 1.9 | 16 | 30 | 90.000 | |

34x126 | C | 1080 | 1450 | 1.6 | 14 | 34 | 70.000 |

C++ | 1200 | 1650 | 1.6 | 18 | 34 | 70.000 | |

D | 1350 | 1800 | 1.9 | 16 | 34 | 90.000 | |

38x126 38x137 | C | 1360 | 1810 | 1.6 | 14 | 38 | 70.000 |

C++ | 1500 | 2040 | 1.6 | 18 | 38 | 90.000 | |

D | 1700 | 2270 | 1.9 | 16 | 38 | 90.000 | |

42x137 42x146 | C | 1660 | 2200 | 1.6 | 14 | 42 | 70.000 |

C++ | 1800 | 2500 | 1.6 | 18 | 42 | 90.000 | |

D | 2070 | 2770 | 1.9 | 16 | 42 | 90.000 | |

Material: carbon steel high carbon steel, manganese steel,20MN2 steel,25mnV steel,23MnNiCrMo54 steel

Chain treatment process: heat treatment, carburizing, blackening, electrophoresis, shot blasting

DIN chain, also known as German standard chain, can be divided into the following standards, DIN 766 chain (short link chain), DIN 764 chain (medium link chain), DIN 763 chain (long link chain), DIN 5685 chain, DIN 22252 chain