Our staff will contact you within 12 hours, You can also contact us through the following ways:

Contact US WhatsApp: +8618766656705

- Email: [email protected]

- Tel: +8618766656705

- Web: https://www.toponechain.com/

Mine gal chain, galvanized mining chain, mine conveyor chain, corrosion-resistant chain, mining round link chain

The mine gal chain is a type of round link chain specially designed for mining and bulk material handling applications. It is manufactured from high-quality alloy steel and then hot-dip galvanized to provide enhanced corrosion resistance in humid or harsh environments.

Known for its strength, durability, and resistance to wear and rust, the mine gal chain is ideal for underground mining operations, open-pit mines, and heavy industrial use. The galvanization layer ensures longer service life compared with standard mining chains, especially in conditions exposed to moisture, chemicals, or abrasive materials.

This type of chain is widely used in conveyor systems, flight bar chain assemblies, lifting equipment, and material transport systems within the mining industry. It is available in various sizes, grades, and galvanization thicknesses to meet different operational requirements. Often, it is combined with sprockets, connectors, and attachments to form a complete mining conveyor or lifting solution.

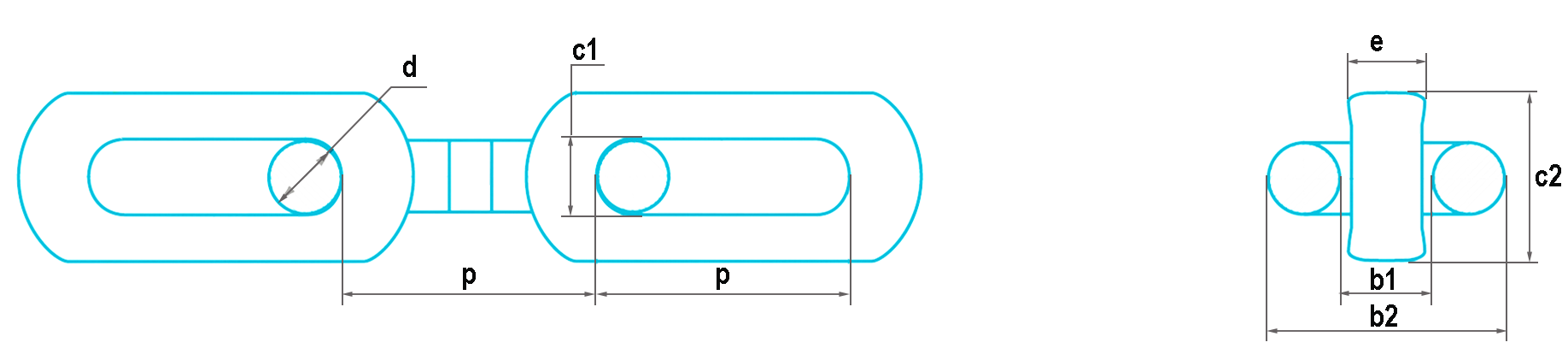

Dimension | ||||||||

Chain Size | Diameter | Pitch | Round Horizontal Link | Flat Vertical Link | e max | Weight | ||

d x p (mm) | d (mm) | P (mm) | b1 min, (mm) | b2 max. (mm) | c1 min. (mm) | c2 max. (mm) | (mm) | (kg) |

26x92 | 26 ±0.8 | 92 ±0.9 | 30.1 | 87 | 30 | 75 | 30.0 | 13.7 |

30x108 | 30 ±0.9 | 108 ±1.1 | 34.1 | 99 | 34 | 87 | 34.0 | 18.0 |

34x126 | 34 ±1.0 | 126 ±1.3 | 38.1 | 111 | 38 | 99 | 38.0 | 22.7 |

38x126 | 38 ±1.1 | 126 ±1.3 | 42.1 | 123 | 42 | 111 | 42.0 | 30.1 |

38x137 | 38 ±1.1 | 137 ±1.4 | 42.1 | 123 | 42 | 111 | 42.0 | 29.0 |

38x146 | 38 ±1.1 | 146 ±1.5 | 42.1 | 123 | 42 | 111 | 42.0 | 27.6 |

42x137 | 42 ±1.1 | 137 ±1.4 | 18.6 | 139 | 46 | 115 | 48.5 | 37.0 |

42x146 | 42 ±1.1 | 146 ±1.5 | 48.6 | 139 | 46 | 115 | 48.5 | 36.0 |

42x152 | 42 ±1.4 | 152 ±1.5 | 54 | 127 | 56.0 | 47.0 | ||

Mechanical Properties | |||||||

Chain Size d x p | Chain Grade | Measuring Force | Test Force | Breaking Force min. | Unit Elongation at test force max. | Unit Elongation at breaking force min. | Fatigue Resistance min. |

(mm) | (KN) | (KN) | (KN) | (%) | (%) | (cycles) | |

26x92

| C | 26 | 637 | 850 | 1.6 | 11 | 70.000 |

C++ | 26 | 700 | 970 | 1.6 | 14 | 70.000 | |

D | 26 | 740 | 1060 | 1.4 | 11 | 90.000 | |

30x108

| C | 35 | 848 | 1130 | 1.6 | 11 | 70.000 |

C++ | 35 | 950 | 1280 | 1.6 | 14 | 70.000 | |

D | 35 | 990 | 1400 | 1.4 | 11 | 90.000 | |

34x126 | C | 45 | 1090 | 1450 | 1.6 | 11 | 70.000 |

C++ | 45 | 1200 | 1650 | 1.6 | 14 | 70.000 | |

D | 45 | 1270 | 1800 | 1.4 | 11 | 90.000 | |

38x126 38x137 38x146 | C | 57 | 1360 | 1820 | 1.6 | 11 | 70.000 |

C++ | 57 | 1500 | 2040 | 1.6 | 14 | 70.000 | |

D | 57 | 1590 | 2270 | 1.4 | 11 | 90.000 | |

42x146 | C | 69 | 1660 | 2220 | 1.6 | 11 | 70.000 |

C++ | 69 | 1800 | 2500 | 1.6 | 14 | 70.000 | |

D | 69 | 1940 | 2770 | 1.4 | 11 | 90.000 | |