Our staff will contact you within 12 hours, You can also contact us through the following ways:

Contact US WhatsApp: +8618766656705

- Email: [email protected]

- Tel: +8618766656705

- Web: https://www.toponechain.com/

High-test (HT) carbon steel anchor / windlass chain made to ISO specifications with short links

Short links make chain more flexible – ideally suited as windlass chain and less likely to tangle in the chain locker

Links are calibrated to fit most any windlass wildcat with an "HT" designation*

High test chain is widely used for its "strength-to-link" factor – working load limit is approximately twice that of BBB or proof coil chain of comparable size

Extra-thick hot dip galvanized finish offers superior corrosion protection and is recommended for all marine applications

Links are identified with an embossed "G4" mark

G43 chain is factory tested to twice its working load limit to ensure quality and reliability

Grade 43 chain is a steel chain that possess greater tensile strength than Proof Coil Chain. Grade 43 Binder Chains typically has a 50% higher working load limit than Proof Coil or Grade 30 Chain. . G43 binder chains are also referred to as High Test Tow Chains, or Log Chains. Grade 43 Chain is NOT approved for overhead lifting. The Binder chains are supplied with a clevis grab hook on each end.

Grade of Chain: NACM (National Association of Chain Manufacturers & ASTM (American Society for Test Materials) classify chains in various grades. The higher the grade, the higher the working load limit for the same size of chain.

Working Load Limit (WLL): (rated capacity) Is the maximum working load that should be applied In direct tension to an undamaged straight length of chain.

Proof Test: (manufacturing test force) Is a term designating the minimum tensile force which has been applied to a chain under a constantly increasing force In direct tension during the manufacturing process. These loads are manufacturing integrity tests and shall not be used as criteria for service or design purpose.

Minimum Breaking Force: The minimum force at which the chain during manufacture has been found by testing to break when a constantly increasing force is applied in direct tension. Breaking force values are not guarantees that all chain segments will endure these loads. This test is a manufacturer’s attribute acceptance test and SHALL NOT be used as criteria for service and design purpose.

Overhead Lifting: The process of lifting that would elevate a freely suspended load to such a position that dropping a load would present a possibility of bodily injury or Property damage.

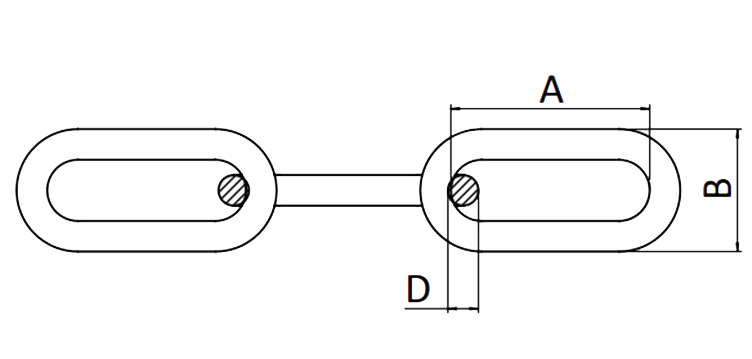

| Size D | Inside Lenght A | Outside Width B | Working Load | Test Load | Breaking Load | Weight Per M | |||

| MM | +/-MM | MM | +/-MM | MM | +/-MM | KG | N | N | KG |

| 3 | 0.5 | 26 | 1.2 | 12 | 0.6 | 55 | 1050 | 3200 | 0.15 |

| 4 | 32 | 1.5 | 16 | 0.8 | 100 | 2000 | 6000 | 0.27 | |

| 5 | 35 | 1.8 | 20 | 1 | 160 | 3150 | 10000 | 0.43 | |

| 6 | 42 | 2 | 24 | 1.2 | 224 | 4500 | 14000 | 0.63 | |

| 7 | 49 | 2.5 | 28 | 1.4 | 300 | 6000 | 18000 | 0.86 | |

| 8 | 52 | 2.5 | 32 | 1.6 | 400 | 8000 | 25000 | 1.1 | |

| 9 | 59 | 3 | 36 | 1.8 | 530 | 10500 | 32000 | 1.41 | |

| 10 | 1 | 65 | 3.2 | 40 | 2 | 630 | 12500 | 40000 | 1.75 |

| 11 | 72 | 3.4 | 44 | 2 | 790 | 15800 | 47500 | 2.11 | |

| 12 | 78 | 3.6 | 48 | 2.3 | 940 | 18800 | 56500 | 2.55 | |

| 13 | 82 | 4 | 52 | 2.5 | 1000 | 21200 | 63000 | 2.95 | |

| 16 | 100 | 5 | 64 | 3.2 | 1600 | 33000 | 100000 | 4.45 | |

| 18 | 113 | 5.2 | 70 | 3.2 | 2120 | 42300 | 127000 | 5.65 | |

| 19 | 119 | 5.6 | 72 | 3.4 | 2370 | 47300 | 142000 | 6.25 | |

| 20 | 120 | 6 | 75 | 3.8 | 2500 | 50000 | 160000 | 7 | |

| 22 | 127 | 6 | 82 | 4 | 3170 | 63300 | 190000 | 8.55 | |

| 25 | 140 | 6.6 | 88 | 4.2 | 4090 | 81700 | 245000 | 10.9 | |

| 28 | 152 | 7 | 96 | 4.7 | 6000 | 120000 | 300000 | 13.9 | |

| 32 | 171 | 7.8 | 108 | 5.2 | 8000 | 160000 | 400000 | 18.2 | |